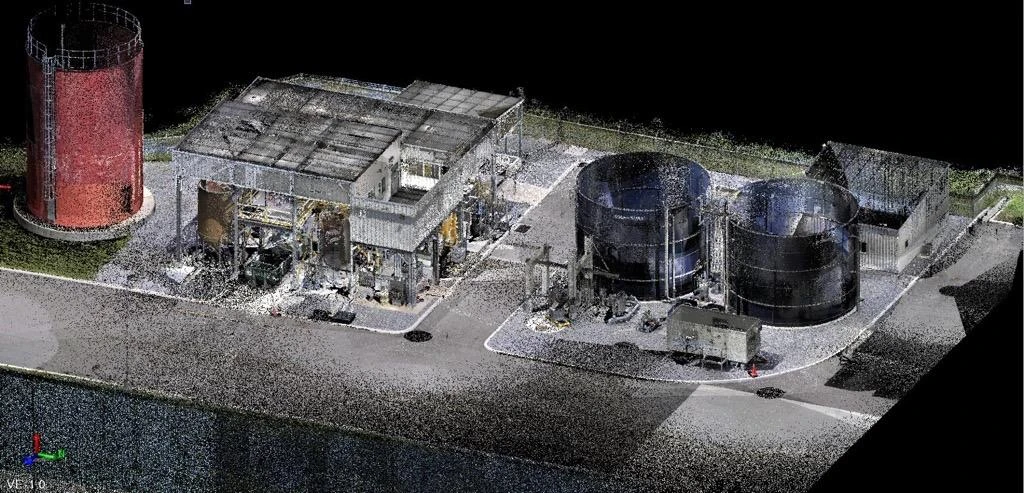

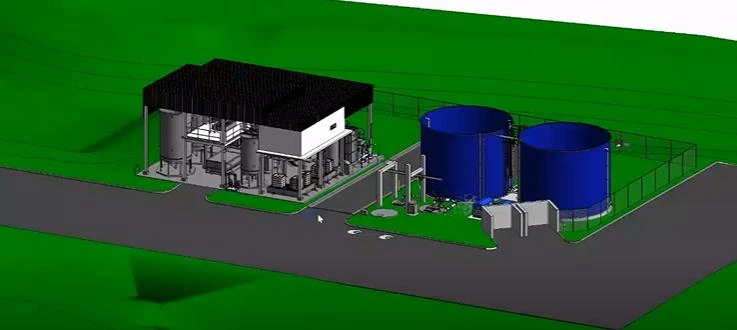

Florida Can Manufacturing Wastewater Treatment Plant

Project Overview

In the heart of Winter Haven, Florida, an ambitious industrial venture was taking shape. Florida Can Manufacturing, a state-of-the-art aluminum can facility, has the capacity to produce over 4,000 cans per minute. But behind this rapid production stood an equally important challenge managing the oily and greasy wastewater generated by the intense manufacturing process.

A New Facility, a New Challenge

From the very start, ECR Engineering was brought in thanks to past project references to tackle one of the key infrastructure needs of the facility: designing an efficient and compliant wastewater treatment system. The challenge was unique. As part of its operation, Florida Can used oil and grease as lubricants in the can-molding process. The result? A wastewater stream with a complex mix of industrial residues. Our first hurdle was determining a representative characterization of this wastewater. Without it, designing the right treatment process would be impossible.

Evolving Through Change

The project evolved through various stages, adapting along the way to significant budget changes. Despite the challenges, our design team remained focused on delivering a system that met both the technical needs and financial boundaries of the client.

The Technical Core

With a total investment of $3.0 million, our solution was an industrial wastewater treatment plant based on chemical and physical processes. The centerpiece of the system was the implementation of DAF (Dissolved Air Flotation) technology to remove oils and grease, paired with a plate filter press to dewater the collected solids. This setup was critical in ensuring compliance with the city’s discharge limits and protecting the surrounding environment.

This effort was made possible by the combined expertise of professionals in process design and coordination, hydraulic and mechanical design, electrical and instrumentation coordination, structural engineering, senior drafting, architectural design, and electrical design from subconsultants.

Environmental Commitment

The project was successfully completed in October 2024, after a design phase that began in February 2020. Thanks to the ECR Engineering team’s strategic planning and innovative approach, the facility now manages all its washing water efficiently and within regulatory standards, setting a solid foundation for sustainable industrial operations in the region.